About Us

PROBALANCE

FOR A MORE ACTIVE AND PAIN-FREE LIFE

Whether you’re looking to live a more active life, relieve pain, or achieve your fitness goals, it’s our mission to help.

Prabalance combines nearly 10 years of expertise in technology and manufacturing with modern research and scientific testing to develop cutting-edge products.

Our products are manufactured in-house in China from materials we source ourselves, allowing for stringent quality control. Our technicians work with medical professionals at the highest levels in sports and medicine to research, develop, and test our supports before you get them.

Building Staffs

Stands for maximum, extreme and potential exploration, and also stands for our commitment to providing the best products and services for sports enthusiasts.

Sport

Emphasizes our love and dedication to sports. We believe that sports can change people's lives and bring them physical and mental health and happiness.

Pro

Stands for professionalism, which means improving the professional protection level of sports, and also shows that we have profound professional knowledge and experience in the field of sports protective gear manufacturing.

30000 ㎡

Factory Area

300

Staff

400

Production Machines

50000

Monthly Output

Professional Manufacturing

PROBALANCE is founded in 2014, located in China,Jiangsu, the factory covers an area of 30,000 square meters. As a professional manufacturer, we are committed to producing high-quality sports protective gear products. We have advanced manufacturing equipment and a professional team to ensure that our products meet high standards and quality requirements through innovative technology and exquisite workmanship.We has our own R&D department, inspection department, weaving, sewing and packaging workshop and so on.

Care and Protection

We pay attention to the health and safety of athletes, and regard health and safety as the most important values of our company. Our products are dedicated to protecting athletes from injury and providing effective sports protection solutions. We hope to provide care and protection for sports enthusiasts through our protective gear products, so that they can enjoy the fun of sports to the fullest.

Innovation and Technology

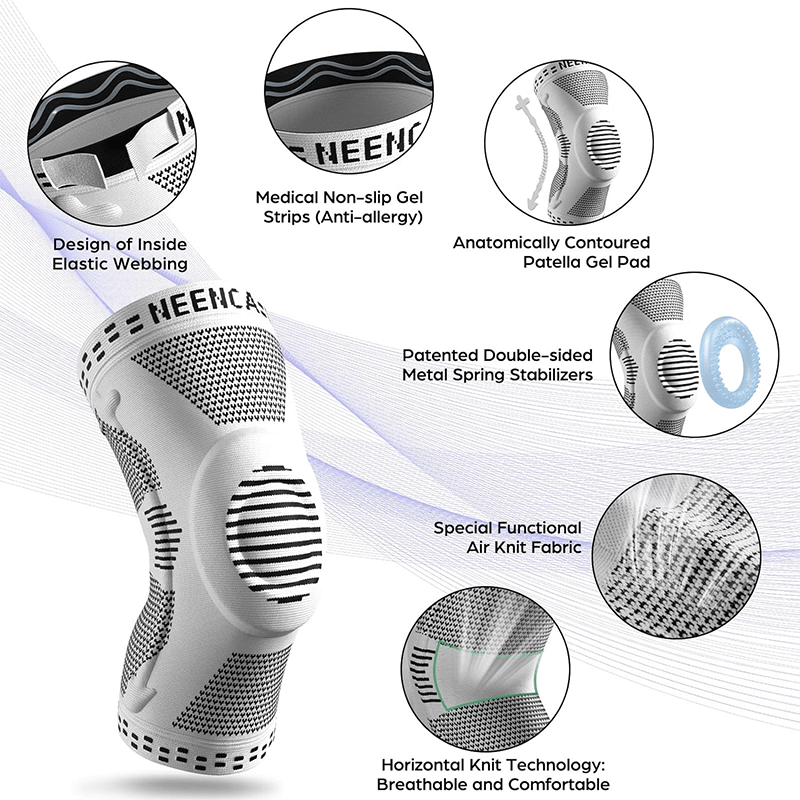

OUR PRODUCTS

Trust Probalance to provide the support you need. We’ve been making compression socks for nearly 10 years and braces for over 10 – and we have never slacked off. To offer you the best possible support, we work closely with globally renowned medical specialists and keep up to date with the latest orthosis research to see if any adjustments need to be made. Currently, we are on the 8th generation of Train supports!

Our products have been tested and proven to minimise pain and improve mobility. All of our compression garments meet the globally recognised RAL—GZ 387 quality assurance standards, ensuring the materials, knitting construction, style, and pressure distribution comply with strict medical requirements.